联系我们,获得免费资源!

联系我们,获得免费资源!

Thomson 精密梯形丝杠

Thomson 精密梯形丝杠

全球最全面的执行器选择方案

Thomson 直线运动系统

请选择您的登录帐户

标准电动梯形丝杠

Rotary Encoders Available as a Standard Option

旋转编码器可提供关于位置、速度及其他诸多实用运动参数的实时反馈。

Thomson提供预装编码器,作为所有步进电机直线推杆的标配。

预制电动梯形丝杠结合了先进的电机和梯形丝杠技术,是高精度直线运动应用的理想选择。

为何选择Thomson电动梯形丝杠?

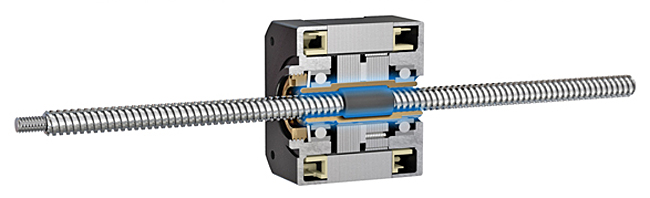

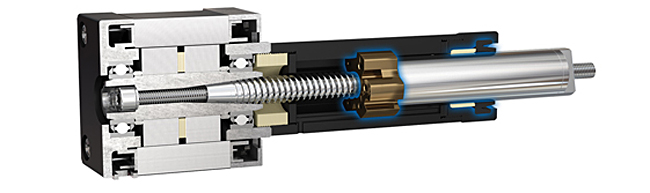

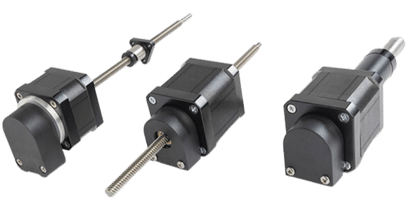

Thomson提供两种基本配置──旋转丝杠(MLS)与旋转螺母(MLN)。开放式结构的旋转丝杠及旋转螺母电动梯形丝杠,适合已具备外部导向或需要高度设计灵活性的应用场景;而若要进一步简化设计流程,且消除对外部导向的依赖,封闭式电动梯形丝杠推杆组件则是理想选择。

电动梯形丝杆定制选项

Thomson与全球原始设备生产商携手合作,解决棘手问题,提高运营效率,力求为生产商的客户提供更高的价值。我们拥有丰富的技术和应用经验,不止能够为您提供标准产品,还可为您量身定制满足您特定需求的产品。

电动梯形丝杆从哪里入手

Thomson提供丰富的在线资源,无论您的购买决策处于哪个阶段,都可以为您提供帮助:

VIDEO: Stepper Motor Linear Actuator Assembly Configurations

Precision lead screws can be combined with a stepper motor in a number of ways. At Thomson, we offer three configurations of stepper motor linear actuators to meet the various needs of our customers' applications. Learn more about them and discover which of them can benefit your linear motion designs.

VIDEO: What is a Stepper Motor and How is it Useful for Linear Motion?

Combined with a precision lead screw, the stepper motor is utilized in one of Thomson’s main product families – stepper motor linear actuators. This video takes a closer look at this motor, its main components, how they work, and why they are useful in linear motion applications in comparison to other types of motors.

技术文章

-

Leveraging Stepper Motor Linear Actuator Configurability

When designers and integrators need simple, flexible and compact linear actuation, they often turn to stepper motor linear actuators (SMLAs). The high configurability of SMLAs is among their greatest virtues, but sorting through myriad configuration options to tailor the optimal solution for a particular application can be a challenge for even the most seasoned motion engineer. Understanding the unique capabilities and limitations of each type of SMLA will make it easier to take maximum advantage of their wide range of flexibility.

Learn More -

为电动梯形丝杠安装防旋转导向装置

为步进电机配置梯形丝杠来实现精密的直线运动方法简单、成本低廉,但需要安装防旋转装置,由用户添加外部装置或生产商设计内置均可。要对您的导向系统进行专门分析,权衡利弊,才能确定何种选择最能适配您的应用。

了解更多 -

只需电动梯形丝杠推杆一个部件,即可将您的直线运动组件化繁为简。

在为机械设计直线运动系统时,系统设计师的选择多不胜数。选择恰到好处才能保证直线运动系统安装简单,节约空间和成本。步进电机和带外部支撑的梯形丝杠组件是实现直线运动的常见驱动装置。但将内置导向和支撑功能集为一体的驱动装置可化繁为简,使用和安装更加方便简单,省去了使用外部部件的烦恼。

了解更多

电动梯形丝杠 - 英制规格

| S = 旋转丝杠(MLS), N = 旋转螺母(MLN) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 直线行程 / 完整步距(μ in.) |

导程 (mm) |

导程符号 (mm) |

电机 | |||||||||

| MLxX8 | MLx11 | MLx14, MLx17 | MLx23 | |||||||||

| 直径符号 [英寸直径的百分之几] | ||||||||||||

| 18 | 18 | 25 | 25 | 31 | 37 | 31 | 37 | 43 | 50 | |||

| 0.063² | 0.013 | 0013 | S | S,N | S¹³ | S¹³ | S,N¹³ | S,N | S¹³ | |||

| 0.125² | 0.025 | 0025 | S | S,N | S¹ | S,N | S¹³ | |||||

| 0.157 | 0.031 | 0031 | S | S,N | S¹ | S,N | ||||||

| 0.165 | 0.033 | 0033 | S¹ | |||||||||

| 0.179 | 0.036 | 0036 | S | S,N | ||||||||

| 0.200 | 0.040 | 0040 | S¹ | S,N | ||||||||

| 0.209 | 0.042 | 0042 | S | S,N | S¹³ | S¹³ | S,N¹³ | S,N | ||||

| 0.250 | 0.050 | 0050 | S | S,N | S | S,N | S¹ | S,N | S¹³ | S¹³ | ||

| 0.313 | 0.063 | 0063 | S | S,N | S | S,N | S¹ | |||||

| 0.357 | 0.071 | 0071 | S | S,N | ||||||||

| 0.394 | 0.079 | 0079 | S | S,N | S¹ | S,N | ||||||

| 0.417 | 0.083 | 0083 | S | S¹ | S,N | S,N | ||||||

| 0.490 | 0.098 | 0098 | S¹ | |||||||||

| 0.500 | 0.100 | 0100 | S | S,N | S | S,N | S¹ | |||||

| 0.591 | 0.118 | 0118 | S | S,N | ||||||||

| 0.625 | 0.125 | 0125 | S | S,N¹ | S | S,N | S¹ | S,N | S¹ | |||

| 0.787 | 0.157 | 0157 | S | S,N | ||||||||

| 0.833 | 0.167 | 0.167 | S | S | S,N | S,N | ||||||

| 0.960 | 0.192 | 0.192 | S | S,N | ||||||||

| 1.000 | 0.200 | 0200 | S | S,N | S | S,N | S¹ | S,N | S¹ | |||

| 1.180 | 0.236 | 0236 | S¹ | |||||||||

| 1.250 | 0.250 | 0250 | S | S,N | S | S | S,N | S,N | S¹ | S¹ | ||

| 1.500 | 0.300 | 0.300 | S¹ | S,N | ||||||||

| 1.665 | 0.333 | 0.333 | S | S,N¹³ | ||||||||

| 1.875 | 0.375 | 0.375 | S | S,N¹³ | S¹ | S,N | ||||||

| 2.000 | 0.400 | 0.400 | S | S,N | ||||||||

| 2.500 | 0.500 | 0500 | S | S,N¹³ | S | S,N | S | S | S,N | S,N | S¹ | S¹ |

| 3.750 | 0.750 | 0750 | S | S,N | S¹³ | S,N | ||||||

| 4.000 | 0.800 | 0.800 | S¹³ | |||||||||

| 5.000 | 1.000 | 1000 | S³ | S³ | S,N³ | S,N³ | S¹³ | |||||

| 6.000 | 1.200 | 1.200 | S¹³ | S,N | ||||||||

| 7.500 | 1.500 | 1.500 | S¹³ | |||||||||

1.某些梯形丝杠可能不提供高性能螺母材料、旋转螺母(MLN)配置或某些消隙螺母。请联系Thomson了解详情。

2. 与传统梯形丝杠相比,细牙梯形丝杠的负载能力也许低很多。

3. 梯形丝杠不提供精密级精度(P)

电动梯形丝杠 - 公制规格

| S = 旋转丝杠(MLS), N = 旋转螺母(MLN) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 直线行程/ 完整步距(mm) |

导程 (mm) |

导程符号² (mm) |

电机 | ||||||||

| MLxX8 | MLx11 | MLx14, MLx17 | MLx23 | ||||||||

| 直径符号 | |||||||||||

| M04 | M04 | M06 | M06 | M08 | M10 | M08 | M10 | M12 | |||

| 3 | 0.6 | 006 | S | S,N | |||||||

| 5 | 1.0 | 010 | S | S,N | S | S,N | |||||

| 6 | 1.2 | 012 | S | S,N | |||||||

| 10 | 2.0 | 020 | S | S | S,N | S,N | S¹ | ||||

| 15 | 3.0 | 030 | S | S,N | S¹ | ||||||

| 20 | 4.0 | 040 | S | S,N | S | S,N | S¹ | ||||

| 25 | 5.0 | 050 | S | S,N | |||||||

| 30 | 6.0 | 060 | S | S,N | S¹ | S,N | S¹ | ||||

| 40 | 8.0 | 080 | S³ | S,N³ | S | S,N | |||||

| 50 | 10.0 | 100 | S | S,N | S¹ | ||||||

| 60 | 12.0 | 120 | S | S,N | S | S¹ | S,N | S,N | |||

| 75 | 15.0 | 150 | S¹ | ||||||||

| 80 | 16.0 | 160 | S¹ | ||||||||

| 90 | 18.0 | 180 | S | S,N | |||||||

| 100 | 20.0 | 200 | S³ | S | S,N³ | S,N | |||||

| 125 | 25.0 | 250 | S¹³ | ||||||||

| 175 | 35.0 | 350 | S¹³ | S,N | |||||||

| 225 | 45.0 | 450 | S¹³ | ||||||||

1.某些梯形丝杠可能不提供高性能螺母材料、旋转螺母(MLN)配置或某些消隙螺母。请联系Thomson了解详情。

3. 梯形丝杠不提供精密级精度(P)

电动梯形丝杠的优势

- 扭矩密度增加

- 效率提升

- 旋转丝杠或旋转螺母

- 可提供定制化尺寸/梯形丝杠

-

锥形锁的优势

-

减少噪音

-

可提供英制/公制版本

应用案例

手册

| Stepper Motor Specification Change Notice | 362 KB | |

| Stepper Motor Linear Actuators | 3733 KB | |

| Stepper Motor Linear Actuators | 3733 KB | |

| Stepper Motor Linear Actuators | 3727 KB | |

| Stepper Motor Linear Actuators | 3629 KB | |

| Stepper Motor Linear Actuators | 3825 KB | |

| Miniature Components and Systems | 6896 KB | |

| Miniature Components and Systems | 6887 KB |

| 2016-01-19 | ||

Choose Your CAD Model:

MLS

MLN

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].